| Application | Hand power tools (drillers from Makita® and Bosch®) |

| Electrical machine | Geared BLDC |

| Supply condition | Run-up at low torque under non sinusoidal supply |

| Noise sources | Electromagnetic, mechanical |

| See also |

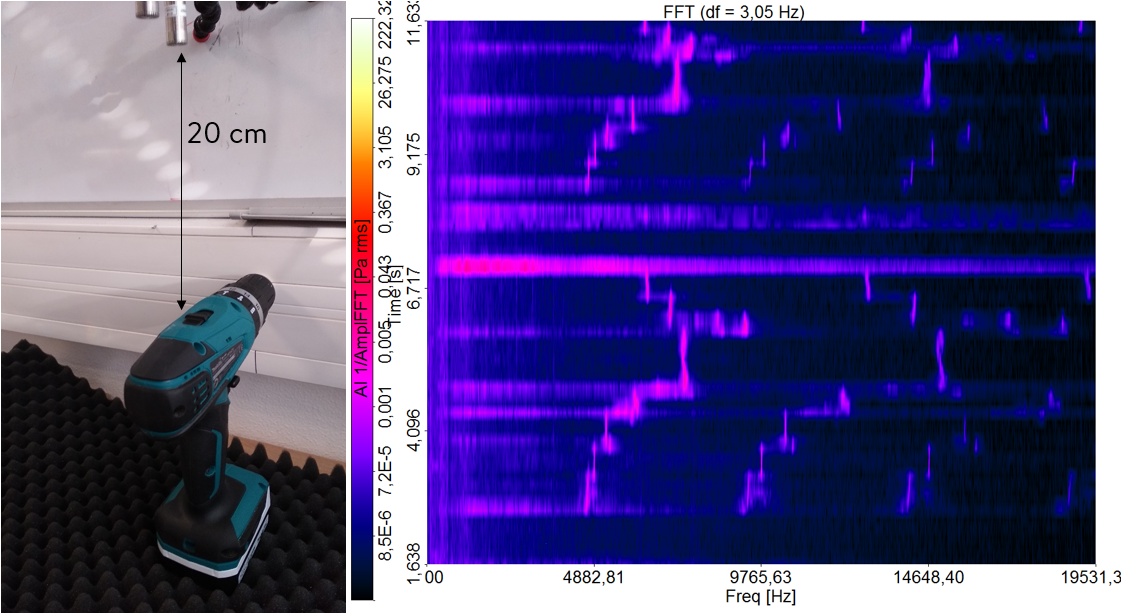

Measurement set-up

Noise is measured 20 cm from the electric powertrain of the drillers. First test is carried at no load, increasing the driller speed up to maximum speed. Second test consists in blocking the rotor manually to obtain maximum torque at very low speed, thus minimizing mechanical noise.

Sound file and spectrograms

Sound of Makita® driller electric powertrain at no load

Sound of Bosch® driller electric powertrain at no load

Note: these sound files are the property of EOMYS; for authorized use in presentations, website, publications or technical work, please contact us

E-NVH interpretations

When starting the electric driller, mechanical noise is rather low and electromagnetically-excited noise is significant. Electromagnetic noise

at low speed is due to Pulse Width Modulation.

For Makita driller the switching frequency increases with discrete steps according to driller speed (synchronous discontinuous PWM). On the contrary Bosch driller has a fixed switching frequency (asynchronous PWM) close to 8 kHz. At higher rotational speed, the PWM noise is masked by the mechanical noise of the gears.

Application to MANATEE

MANATEE software can be used to quickly calculate NVH due to electromagnetic forces both in early design and detailed design phase, including PWM and slotting effects.