| Application | Nissan Leaf® (EV HEV NVH) |

| Electrical machine | IPMSM (48 stator slots, 8 poles) |

| Supply condition | Run-up at max torque |

| Noise sources | Electromagnetic, mechanical, aerodynamic |

| See also | Renault Zoe, Tesla X90 |

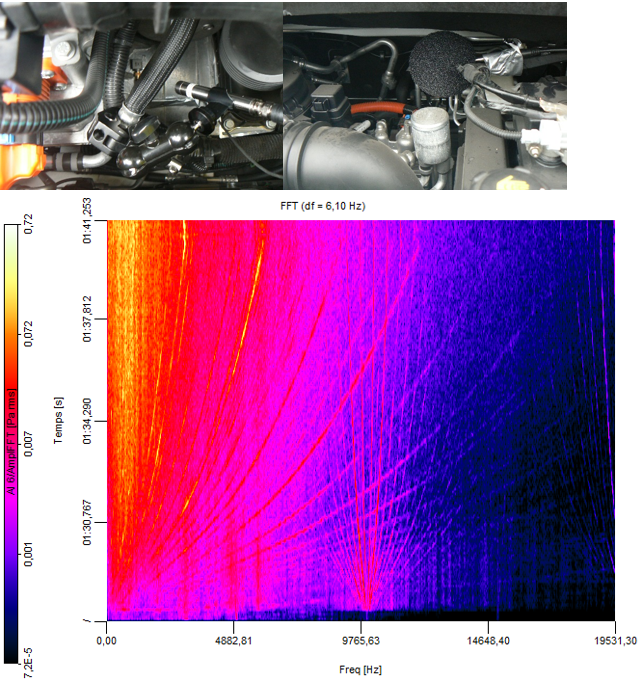

Measurement set-up

Noise is measured close to electric powertrain and at driver’s hear. A 3d accelerometer is placed on the stator housing in the middle of the lamination. A run-up is done with maximum torque up to 100 km/h in free field environment. Eco mode is not activated but AVAS is activated.

Sound file and spectrograms

Sound of Renault® Zoe electric powertrain during run-up at maximum torque

Note: these sound files are the property of EOMYS; for authorized use in presentations, website, publications or technical work, please contact us

E-NVH interpretations

This sound file illustrates electromagnetically-excited noise of the electric powertrain of Nissan Leaf EV. High pitch, whining noise with increasing frequency is due to pole/slot electromagnetic excitations. Higher frequency sound occuring around multiples of 5 kHz is due to PWM effects with asynchronous switching frequencies. Some resonances can be visible in the spectrogram near 8 kHz which corresponds to the match between electromagnetic forces of wavenumber 0 and breathing mode natural frequency of the stator lamination housing assembly. As seen in most EV HEV NVH studies, stator breathing mode is responsible for high-pitch airborne noise. One can also notice that the noise at twice the switching frequency reaches a maximum at mid-speed which reflects the evolution of inverter current harmonic magnitude with increasing modulation index. The AVAS alerting system can be audible at low speed around 2kHz.

Application to MANATEE

MANATEE software can be used to quickly calculate EV HEV NVH due to electromagnetic forces both in early design and detailed design phase, including PWM and slotting effects.